- Any questions?

- +49 (0) 2623 - 20 90

- info@germatec.de

- Select language:

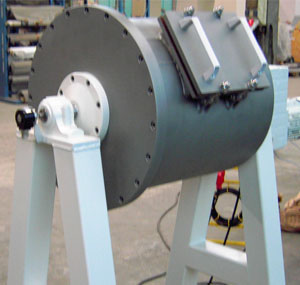

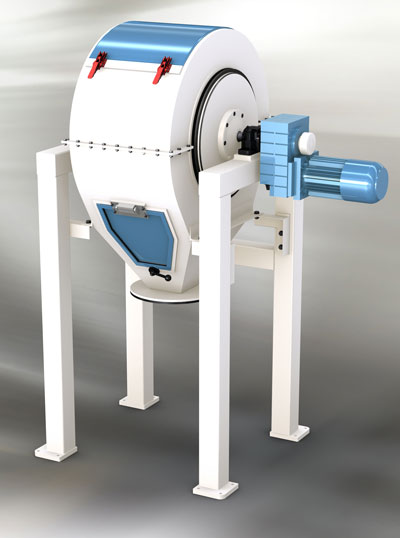

In order to prepare processing, the particular bodies and materials have to be treated in suitable manner. According to intended purpose, the grinding and mixing units have to comply with various requirements.

All grinding and mixing units, such as ball mills as well as wet and dry process drum mills can be coated with various materials, like rubber, polyurethane or ceramic lining.

For dust-free discharge, the dry process mills will be equipped with a dust hood.

The one-piece drum out of special porcelain is produced without any gaps. By this, the drum can be cleaned easily in case of frequent product changeover.

Based on our longstanding experience, we can offer you the suitable equipment for almost any task.

To our service portfolio for grinding equipment, proved over many decades and practice-tested, belong the following machines:

Jar mills or roller mills for wet and dry grinding as well as mixing of different materials in suitable round-shaped recipients out of porcelain, plastics, steel, stainless steel or similar.

As an option, the machine can be equipped with frequency inverter for infinitely variable speed control.

Jar mills or roller mills for wet and dry grinding as well as mixing of different materials in suitable round-shaped recipients out of porcelain, plastics, steel, stainless steel or similar.

Option: Each level with separate drive, infinitely variable speed control by means of frequency inverter.

Universal roller for wet and dry grinding as well as mixing of different materials in suitable round-shaped recipients out of porcelain, plastics, steel, stainless steel or similar.