- Any questions?

- +49 (0) 2623 - 20 90

- info@germatec.de

- Select language:

This valuable machine has many names, but only one single task.

On the principle of a screw conveyor, extruders press solid to viscous bodies smoothly out of a shaping mouthpiece. According to Wikipedia, this procedure is called extrusion.

GERMATEC extruders are the optimum solution for this task and will support your manufacturing process by means of high reliability and long lifetime of the machines.

A capital investment of lasting value with full return on investment (ROI) within a short period of time and rapid amortization.

To our service portfolio for material preparing machines, proved over many decades and practice-tested, belong the following machines:

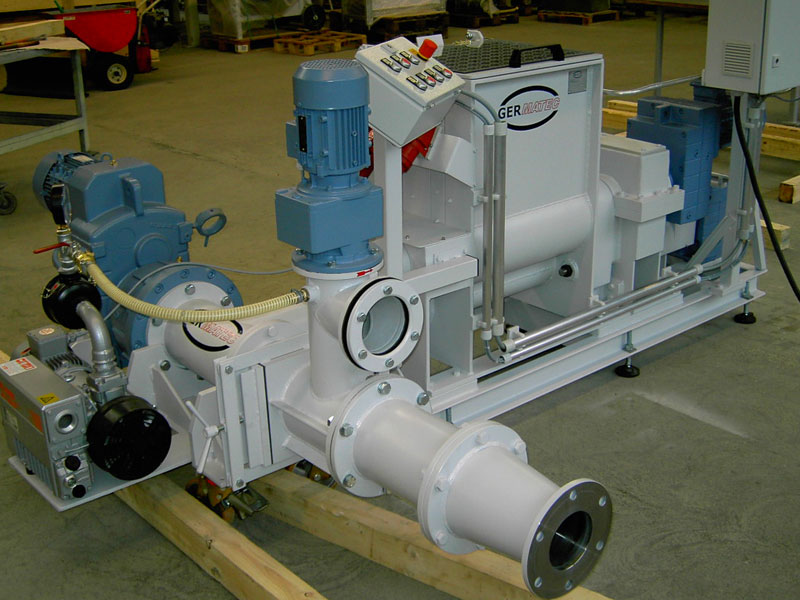

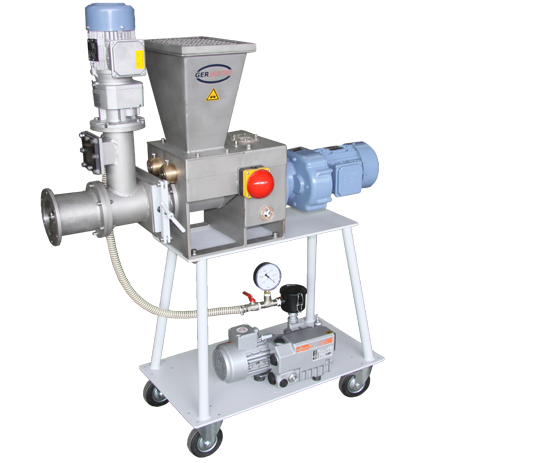

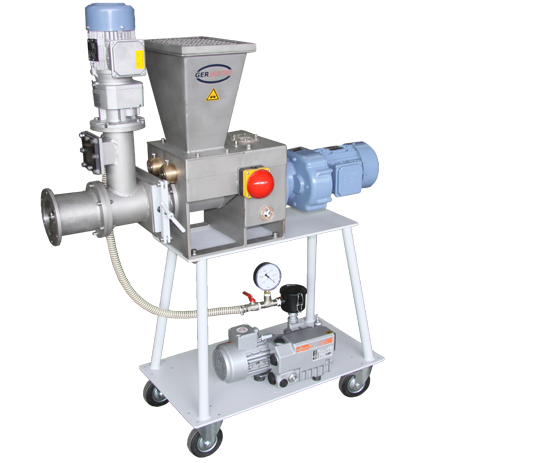

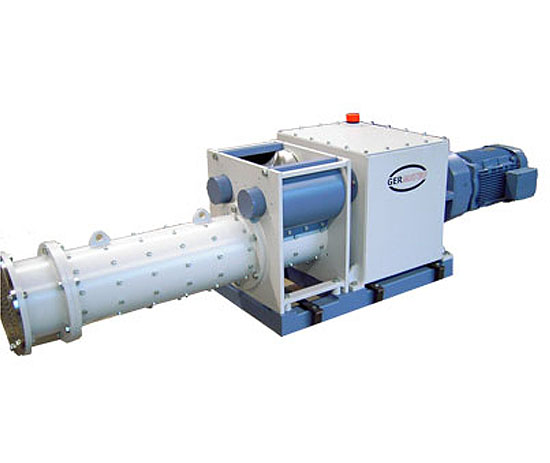

Vacuum extruders are used for further processing of appropriately prepared plasticized bodies, which will be extruded through suitable dies as workable columns or profiles. As an option, the extruder can be equipped with infinitely variable speed control by frequency inverter.

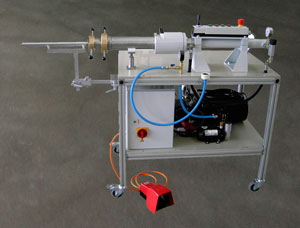

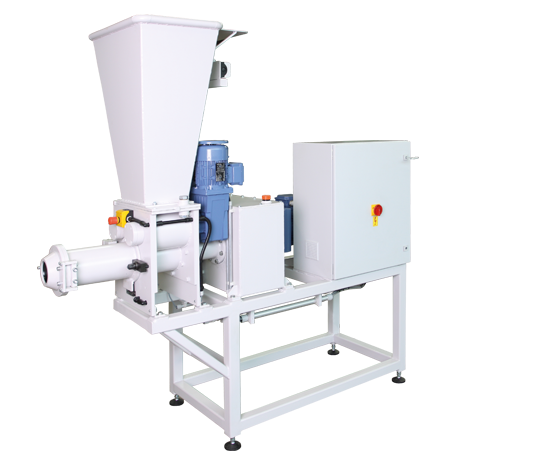

Extruders are used for further processing of appropriately prepared plasticized bodies, which will be extruded through suitable dies as workable columns or profiles. As an option, the extruder can be equipped with infinitely variable speed control by frequency inverter.

Extruder without vacuum with firmly mounted worm shaft and extendable worm segments.